EQuip Inventory Detailed Features

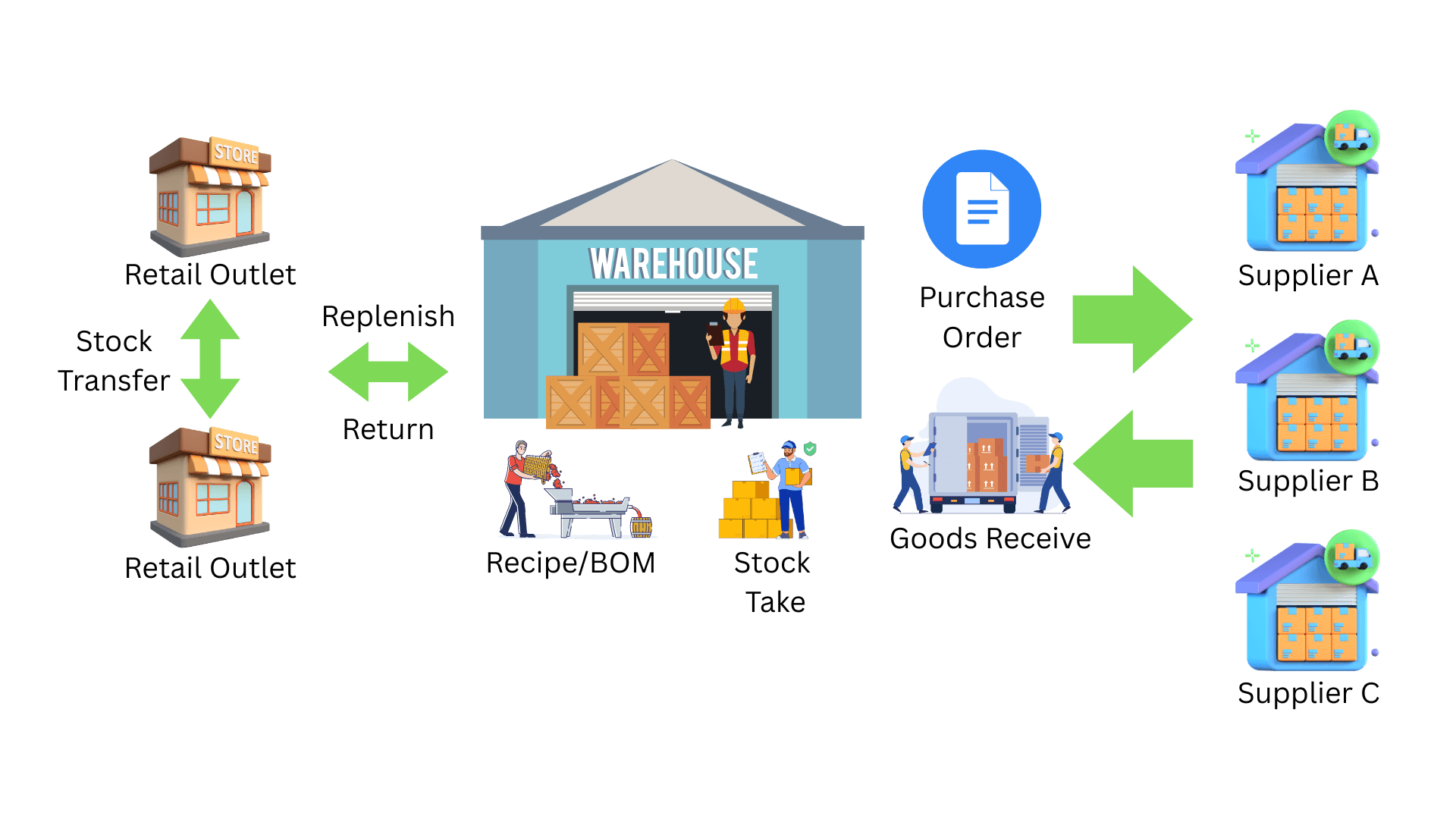

How EQuip Inventory Works: From Suppliers to Customers

The diagram above shows the complete EQuip inventory ecosystem—a connected system where every component works together seamlessly. Your central warehouse acts as the hub, receiving goods from multiple suppliers through purchase orders, managing stock with precision through our goods receiving process, and distributing inventory to your retail outlets based on real demand.

Whether you’re replenishing outlets from the warehouse, transferring stock between retail locations, processing returns to suppliers, or managing production in a central kitchen, EQuip tracks every movement with complete accuracy and real-time visibility. The system automatically updates inventory levels, calculates costs, and maintains comprehensive audit trails across all transactions.

Let’s dive into each component to see exactly how EQuip transforms your inventory operations.

1. Supplier & Purchase Order Management

Multi-Supplier Coordination

EQuip allows you to manage unlimited suppliers within a single system. For each product in your inventory, you can assign multiple suppliers, giving you flexibility in sourcing and maintaining reliable supply chains. The system allows you to set a preferred supplier for each product, streamlining the procurement process.

Purchase Order Creation

The Purchase Order (PO) feature enables businesses to streamline their procurement process and manage purchases from suppliers efficiently. The system allows you to:

- Create purchase orders for specific locations (warehouse or outlets)

- Select suppliers and add items that belong to those suppliers

- Specify quantities, unit prices, and delivery dates

- Edit or update POs before submission

- Track PO status (pending, approved, or rejected)

Purchase Order Workflow

The standard PO process follows these steps:

- Create Purchase Order: Select the location, supplier, and add items to the PO

- Save as Pending: PO is saved in pending status

- Send for Approval: Submit the PO for review

- Approval Process: Reviewers can adjust quantities if needed and approve or reject the PO

- Send to Supplier: Once approved, the PO is sent to the supplier (currently done manually outside the system)

Automated Reordering with Min-Max Levels

EQuip includes a product min-max feature that allows you to define minimum and maximum inventory levels for each product. This proactive approach to inventory management works as follows:

- Minimum Stock Level: When actual stock falls below this level, the system alerts you that it’s time to reorder

- Maximum Stock Level: Represents the upper limit for inventory quantity, preventing overstocking

- Automatic PO Creation: When enabled, the system automatically creates purchase orders for items below minimum quantity, routing them for approval

This feature ensures you maintain optimal inventory levels while avoiding both stockouts and excess inventory holding costs.

Supplier Portal

The Supplier Portal Module enables external suppliers to create and manage purchase orders directly within your system:

- Supplier Access: External suppliers can register and log in with their credentials

- User-Supplier Mapping: Users are mapped to specific suppliers and can only view items and orders relevant to their supplier relationship

- PO Creation: Suppliers can create purchase orders with order dates, delivery dates, and item quantities

- Amendment Capability: Suppliers can amend purchase orders before submitting for internal approval

- Two-Step Approval: Once submitted, POs are routed to finance or designated approvers for review, comments, and final approval or rejection

- Dashboard Overview: Suppliers can view current and past purchase orders with their status and details

Purchase Requisition

The Purchase Requisition Module empowers non-finance users (such as central kitchen operators) to create purchase requests that can be converted into purchase orders:

- Users specify items and quantities needed

- Requests undergo review before conversion to POs

- Consolidation Feature: Multiple purchase requests can be intelligently combined into a single purchase order, enhancing efficiency and leveraging bulk purchasing power

- Eliminates manual data entry and reduces errors when creating POs

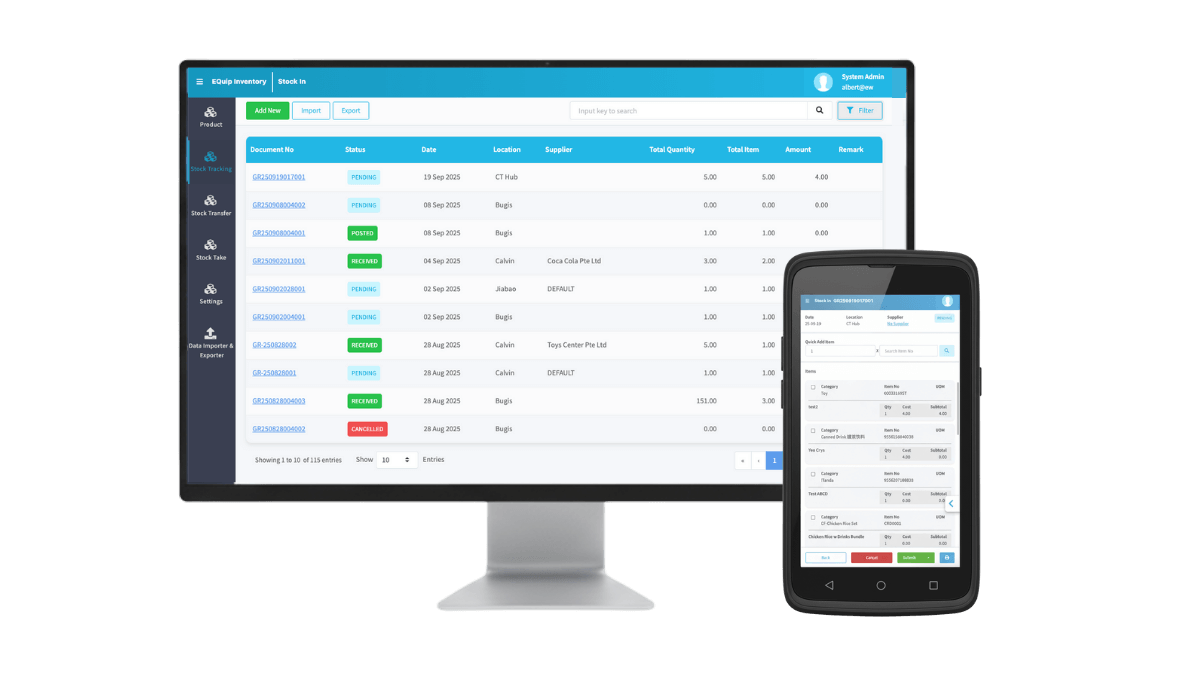

2. Goods Receiving & Warehouse Operations

Streamlined Receiving Process

When goods arrive from suppliers based on approved purchase orders, EQuip’s Goods Receipt feature enables accurate and efficient receiving:

- Scan the PO: Use barcode scanning to quickly access the purchase order

- Two Receiving Methods:

- Blind Receive: Receiving personnel must scan all items and enter counted quantities without seeing the PO details. This enforces accurate counting and prevents assumptions

- Load All Items: All PO items are pre-loaded; staff check quantities and amend as needed. This faster method is useful when manpower is limited

- Submit Goods Receipt: Quantities are automatically updated and average cost prices are recalculated

Partial and Full Goods Receiving

Partial Goods Receive

When suppliers cannot fulfill entire orders at once, the Partial Goods Receive feature allows you to:

- Accept and record partial deliveries

- Choose to close the PO or leave it open for future deliveries

- Automatically cancel undelivered items if the PO is closed

- Monitor pending items until fully received

Full Goods Receive

When all items in a purchase order are delivered at once, users can receive all items with a single action. The system automatically updates inventory with complete receipt details.

Cost Price Calculation

EQuip uses the weighted average cost price method for inventory valuation. Item cost prices are automatically calculated whenever:

- Goods are received from suppliers

- Items are transferred between locations

Note: The system uses weighted average cost calculation exclusively and does not support FIFO or other costing methods.

3. Central Warehouse Management

Product Organization & Hierarchy

EQuip incorporates a hierarchical structure to organize inventory effectively:

- Item Departments: The highest level of categorization (e.g., “Electronics”)

- Categories: Multiple categories under each department group similar products (e.g., “Mobile Phones,” “Laptops,” “Accessories”)

- Product Attributes: Define characteristics that distinguish product variations

- Multiple Barcodes: Assign unlimited alternate barcodes to each item for flexible scanning and tracking

Multiple Units of Measurement

The system provides flexibility in handling different units of measurement (UOM) for each product:

- Products can be sold, purchased, or managed in multiple units (e.g., kilograms and pounds, liters and gallons)

- Define conversion ratios between different UOMs

- System automatically calculates and records quantities based on the base UOM, ensuring consistency across all processes

Stock Take & Cycle Counting

Stock take is a crucial process where physical counts are conducted to verify actual inventory quantities against system records. EQuip provides comprehensive tools for this essential function.

Partial and Full Stock Take

- Partial Stock Take: Count only specific sections of inventory, useful for large warehouses or during busy periods. Remaining stock balances are not changed for uncounted items

- Full Stock Take: Count the entire inventory. Items not submitted during stock take are set to 0 physical count, accounting for SKUs that have been fully sold out

Bin Function

The Bin function divides larger locations (warehouses or outlets) into smaller, specific sections:

- Each bin represents a distinct sublocation where certain items are stored

- Enables more accurate and focused inventory counting

- Reduces errors and confusion during stock take

- When the same item is stored in multiple bins, physical counts are automatically summed

Set Stock Take Date and Time

Critical feature that ensures accurate inventory snapshots:

- Set a specific date and time for when the stock take occurs

- System captures quantities counted at that exact moment

- Stock activities after this time are not considered for quantity adjustments

- Continue Operations During Verification: Stock movement, sales, and other activities can proceed normally while stock take is being verified

- Maintains dynamic, current inventory system even during the verification process

- Enables accurate comparison between physical counts and system records at a specific point in time

Recipe & Bill of Materials (BOM) Management

Essential for F&B businesses with central kitchens or manufacturers assembling products from components.

Recipe/BOM Setup

Define recipes or BOMs that list necessary ingredients or parts with their quantities needed to produce finished products:

- System automatically calculates required inventory levels of components for production orders

- Ensures adequate stock is available for production or cooking

- Multi-level BOMs supported for complex products

Production (Cooking) Function

When production is initiated:

- Planned vs. Actual Quantities: Specify intended production quantity and actual quantity produced (accounting for failures or issues)

- Automatic Deduction: System deducts raw materials used in production from inventory

- Finished Goods Addition: Simultaneously adds finished products to inventory

- Accurate Records: Maintains precise inventory records by tracking both planned and actual production quantities

- Accounts for discrepancies during cooking or manufacturing processes

4. Multi-Location Distribution

Stock Indent (Outlet to Warehouse Ordering)

The Stock Indent feature allows retail outlets to request stock from the central warehouse based on their specific needs.

Stock Indent Workflow

- Create Stock Indent Order: Outlet creates request specifying items and quantities needed

- Supervisor Approval: Supervisor reviews and approves, with ability to amend quantities

- Optional Picklist Process: If enabled:

- Warehouse personnel perform picking by scanning items

- Confirm transfer out; quantities deducted from warehouse after confirmation

- Automatic Deduction: If picklist not enabled, quantities automatically deducted upon approval

- Receiving at Destination: Outlet performs receiving by scanning items when they arrive

- Inventory Update: Quantities updated at outlet location after receiving is complete

Both full and partial delivery of stock indents are supported.

Auto PO When Insufficient Stock

When this feature is enabled:

- If warehouse doesn’t have sufficient quantity to fulfill an outlet’s stock indent, system automatically creates a PO

- PO created in pending state and routed for approval before sending to supplier

- PO is created for the preferred supplier set for the item

- Ensures outlets can get needed stock even when warehouse is low

Inter-Outlet Stock Transfers

The Stock Transfer feature enables seamless movement of stock between different outlets, optimizing inventory distribution across your network.

Stock Transfer Workflow

- Create Stock Transfer Order: Specify source outlet and destination outlet

- Enter Items: Add items to be transferred with quantities

- Supervisor Approval: Supervisor reviews and approves the transfer

- Receiving: Destination outlet performs receiving when goods arrive

- Inventory Update: Stock levels automatically updated at both locations

This feature ensures efficient inventory distribution and helps outlets support each other when stock availability varies across locations.

5. Returns, Adjustments & Stock Management

Stock Issue / Write-off

The Stock Issue function enables you to deduct item quantities from specific locations for non-sales purposes:

Process

- Select the target location from which quantity will be deducted

- Choose items and specify quantities to be issued

- Select reason from predefined dropdown list (e.g., wastage, marketing samples, internal consumption)

- Confirm stock issue to deduct specified quantity from inventory

This function allows accurate tracking of inventory movements and maintains precise records for non-sales deductions.

Stock Adjustments

The Stock Adjustment feature allows manual corrections to recorded stock quantities when discrepancies cannot be attributed to typical stock movements.

When to Use Stock Adjustments

- Damage or theft discovered

- Recording errors identified

- Discrepancies that don’t fit standard categories

Two-Step Approval Process

To ensure proper controls and authorization:

- One staff member creates the stock adjustment

- Another staff member with higher authority approves the adjustment

- This separation ensures only authorized personnel can approve adjustments while allowing lower-level staff to create them

- Maintains accountability and reduces potential for errors or fraud

6. System Administration & Reporting

Master Data Setup

The master data setup function lays the foundation for efficient and controlled inventory operations.

User Setup

- Create and configure user accounts with different privileges and access levels

- Ensure each user can only perform authorized actions within the system

- Enhance security and accountability by granting appropriate permissions based on roles and responsibilities

Location Setup

- Define physical locations where inventory is stored (warehouses, outlets, distribution centers)

- Assign unique attributes and characteristics to each location

- Streamline inventory management with clear organizational structure for stock movements

Bin/Sublocation Setup

- Divide larger locations into smaller, manageable sections called bins

- Facilitate more accurate stock counting

- Provide traceability for items within specific warehouse or outlet areas

- Optimize stock take process and organize inventory for efficient movement and retrieval

Stock Issue Reason Setup

- Create predefined reasons for inventory deductions

- Maintain consistency in recording stock issues

- Gain valuable insights into purposes behind inventory deductions

Comprehensive Reporting

EQuip Inventory offers a range of standard reports providing crucial insights for informed decision-making, efficient inventory control, and optimized supply chain management.

Stock Balance Reports

Standard Stock Balance Report:

- View stock balance of items with inventory values

- Filter by all locations or specific location

- Snapshot of current inventory levels

Stock Balance with Incoming Stock:

- Shows current stock balance plus quantities from pending POs or Stock Orders awaiting delivery

- Greater visibility of future stock levels

- Better planning for upcoming inventory

Stock Balance by Date:

- View historical stock balances for any specific date in the past

- Understand inventory position at any point in time

- Useful for audits and historical analysis

Goods Receive Reports

- Summary Report: Overview of all goods receiving activities

- Detail Report: Detailed information about each goods receipt including items, quantities, costs

- Track when and what was received from suppliers

Stock Transfer Report

- View all stock transfers between locations

- Track stock orders from outlets to warehouse

- Complete visibility of inter-location movements

Stock Adjustment Report

- View history of past stock adjustments

- Track reasons for adjustments

- Monitor adjustment patterns and trends

Stock Take Reports

Stock Take Report:

- View discrepancies between system quantity and actual counted quantity

- Identify areas requiring investigation

Stock Variance Report:

- Shows difference between system balance and stock take count

- Displays variances in both quantity and stock value

- Financial impact of inventory discrepancies

Inventory Activity Report

- Shows every movement in the inventory system at the most granular level

- Displays every single activity for each item at each location

- Complete audit trail of all inventory transactions

- Most detailed report for investigating specific inventory movements

Stock Aging Report

- Shows how old each item is by comparing to past goods receipts

- Calculates age by subtracting GR date from current date

- Identifies slow-moving stock that may need attention

- Helps prevent obsolescence and optimize inventory turnover

- Shows which goods receipts contribute to current stock balance

Why Choose EQuip for Your Business?

Proven Track Record

With over 18 years in the market and 3,000+ satisfied clients across Singapore, EQuip has been refined through thousands of real-world deployments. Our clients range from small family businesses to large enterprises and government organizations—all trusting us with their critical inventory operations.

Comprehensive Features

From purchase orders to production management, from multi-location transfers to detailed reporting, EQuip provides end-to-end inventory management capabilities in one integrated system.

Flexible & Scalable

Whether you’re managing a single warehouse or coordinating dozens of retail outlets, EQuip adapts to your business structure and grows with you as you expand.

Accurate & Reliable

With features like blind receiving, two-step approval processes, and comprehensive audit trails, EQuip ensures inventory accuracy and maintains proper controls throughout your operations.

Ready to Transform Your Inventory Operations?

Whether you’re struggling with stock accuracy, planning multi-location expansion, or simply want better visibility and control over your inventory—EQuip has the solution.

Schedule a personalized demo to see how EQuip can address your specific business challenges. Our team will walk you through the features most relevant to your industry and operations, answer your questions, and help you understand the improvements you can expect.

Edgeworks Solutions Pte Ltd

18+ Years of Excellence | 3,000+ Satisfied Clients

Your Strategic Partner in Business Growth